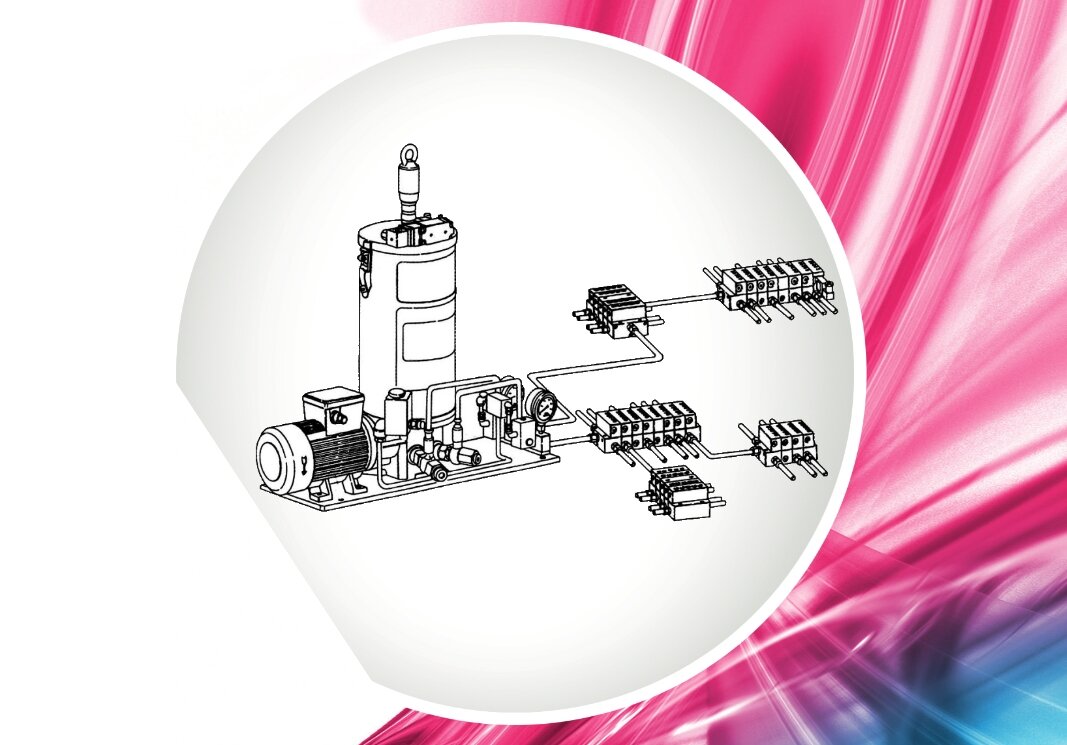

The Centralized Lubrication Systems, in their various types, are now considered an integral part of many modern machines and are increasingly spreading not only in industry but also in the field of heavy automotive transport. Lubrication is certainly one of the main tasks of the personnel in charge of maintaining any type of industrial installation that involves the use of machines. The correct functioning of the production sector and consequently of the entire company depends on it. Manually lubricating machines, that is, applying lubricant to the points that need it using only grease guns or oilers, may be sufficient to ensure good, though not optimal, lubrication. However, this procedure, commonly used until a few decades ago, has the following disadvantages: All the problems generated by the points listed above can be avoided by using a Centralized Lubrication System. The delivery of the lubricant can take place either by manual command, acting on a lever, a handle, or a button, or automatically; in the latter case, the system is able to operate without external intervention except for its maintenance or for refilling the tank from which the grease or oil to be dispensed is drawn. Centralized Lubrication

Purpose of Lubrication

Types of centralized lubrication systems and fields of application

Lubrication systems can be grouped into the following types:

The fields of application range from small machine tools to large plants such as steel mills and cement factories:

These above are just some applications. Others are always possible by choosing the right components according to various needs.

Nexoil, also thanks to the historical experience inherited from the acquisition of the Flenco Lubrication System brand and its know-how, is able to support and advise the customer in choosing the best solution for their application.

Copyright © 2024.

Nexoil s.r.l. - via Fagnano Olona, 27 - 21052 Busto Arsizio (VA) | REA of Varese, Tax Code and VAT No. 03175670128 - Share Capital €100,000.00.

Tel.: +39 011 9342434 - Fax: +39 011 9370532 - Email: info@nexoil.it

INDUSTRIAL CENTRALIZED LUBRICATION

INDUSTRIAL CENTRALIZED LUBRICATION

2024-09-26 15:01

2024-09-26 15:01

Array() no author 90849

Knowledge, nexoil, lubrificazione, sistemalineasingola, sistemadoppialinea, sistemaariaolio, sistemaprogressivo, lubrificazionecentralizzata,

Centralized Lubrication Systems are now to be considered an integral part of many modern machines. The article will highlight their va

Copyright © 2024.

Nexoil s.r.l. - via Fagnano Olona, 27 - 21052 Busto Arsizio (VA) | REA of Varese, Tax Code and VAT No. 03175670128 - Share Capital €100,000.00.

Tel.: +39 011 9342434 - Fax: +39 011 9370532 - Email: info@nexoil.it